Denim Special Edition

Visit Carved in Blue, a blog produced and curated by the denim team at Lenzing.

© Richard Cordero

© Richard Cordero

Introducing Blue Cast: the Denim Insider Podcast

A conversation with friends and colleagues in the course of a late-night taxi ride during the 2019 Kingpins Amsterdam week spawned what now has become our YouTube channel Blue Lenz. This seemed to be a natural extension of the targeted aim behind our blog Carved in Blue, which is to be a proactive member of the global denim community and producer of TENCEL™ Denim.

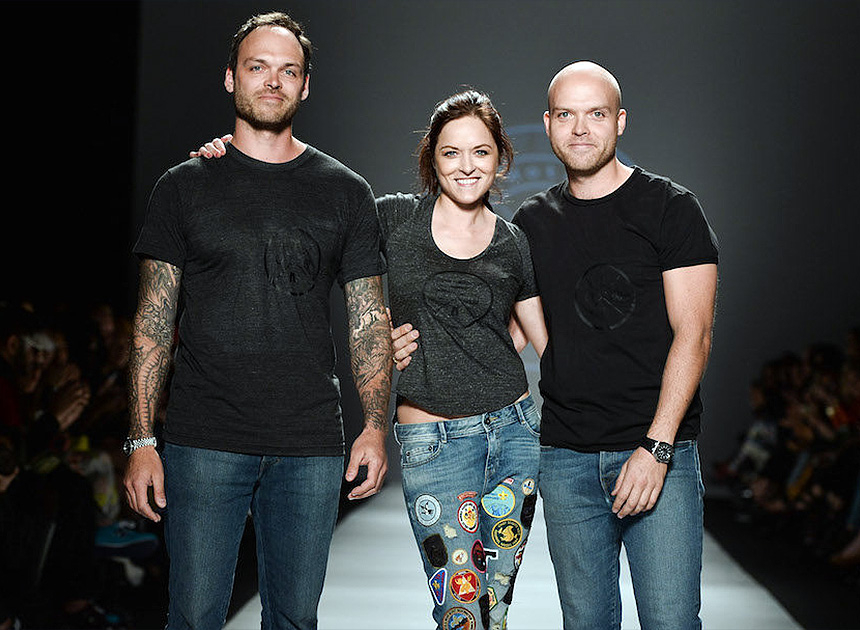

© Adam Taubenfligel

© Adam Taubenfligel

All in the Family with Triarchy’s Adam Taubenfligel

From the start, denim brand Triarchy has been a family affair. Siblings Adam, Ania and Mark Taubenfligel founded Triarchy as a direct-to-consumer label in 2011, leveraging their particular skillsets. Triarchy originally began with a focus on creating great denim, but in 2016 the siblings’ priorities shifted. After five years of operating the brand and seeing the eco impact of jeans firsthand, they decided to change course toward a more environmentally friendly production and business model, successfully relaunching as a sustainability-first brand.

© Soorty

© Soorty

Soorty Says So Long to Seasons in Sustainability Move

This past year has given the fashion industry time to reconsider how it operates. With closed stores, inventory piled up and quickly became outdated as the season changed. Even before Covid-19, about 30 percent of the 150 billion pieces of clothing produced never made it to the sales floor. Furthering the waste, 84 percent of the merchandise that is purchased eventually ends up in a landfill. Denim mill Soorty is breaking free from what it sees as a broken fashion system by ditching traditional seasons in favor of timeless designs.

© Kingpins Show

© Kingpins Show

Ravensbourne Ramps Up Remote Capabilities for Kingpins Project

During Covid, the fashion industry has adapted processes and workflows for the new virtual normal, and education is no exception. The 2020/21 Denim Innovation Project, a collaboration between the Kingpins Show and London’s Ravensbourne University, brought together students in second year BA honors courses to create a new denim brand in just 10 weeks. Using sustainability as a theme, the classes developed designs using fabric and materials provided by sponsors.

© Richard Cordero

© Richard Cordero

Recycling Day Reads: Denim’s Circular Developments

Conventional apparel and textile production is resource intensive. But forward-thinking brands and suppliers are rethinking their practices to create circular systems with less environmental impact.Here at Lenzing, we’re committed to circularity. The closed loop production for TENCEL™ Lyocell recovers more than 99 percent of the solvent and reuses it. Our TENCEL™ x REFIBRA™ technology takes circularity a step further by reusing cotton fabric scraps and turning it into new lyocell through a chemical recycling process. This creates a circular path for some of the 10 to 30 percent of textiles that are left over after the cutting process. Read more…